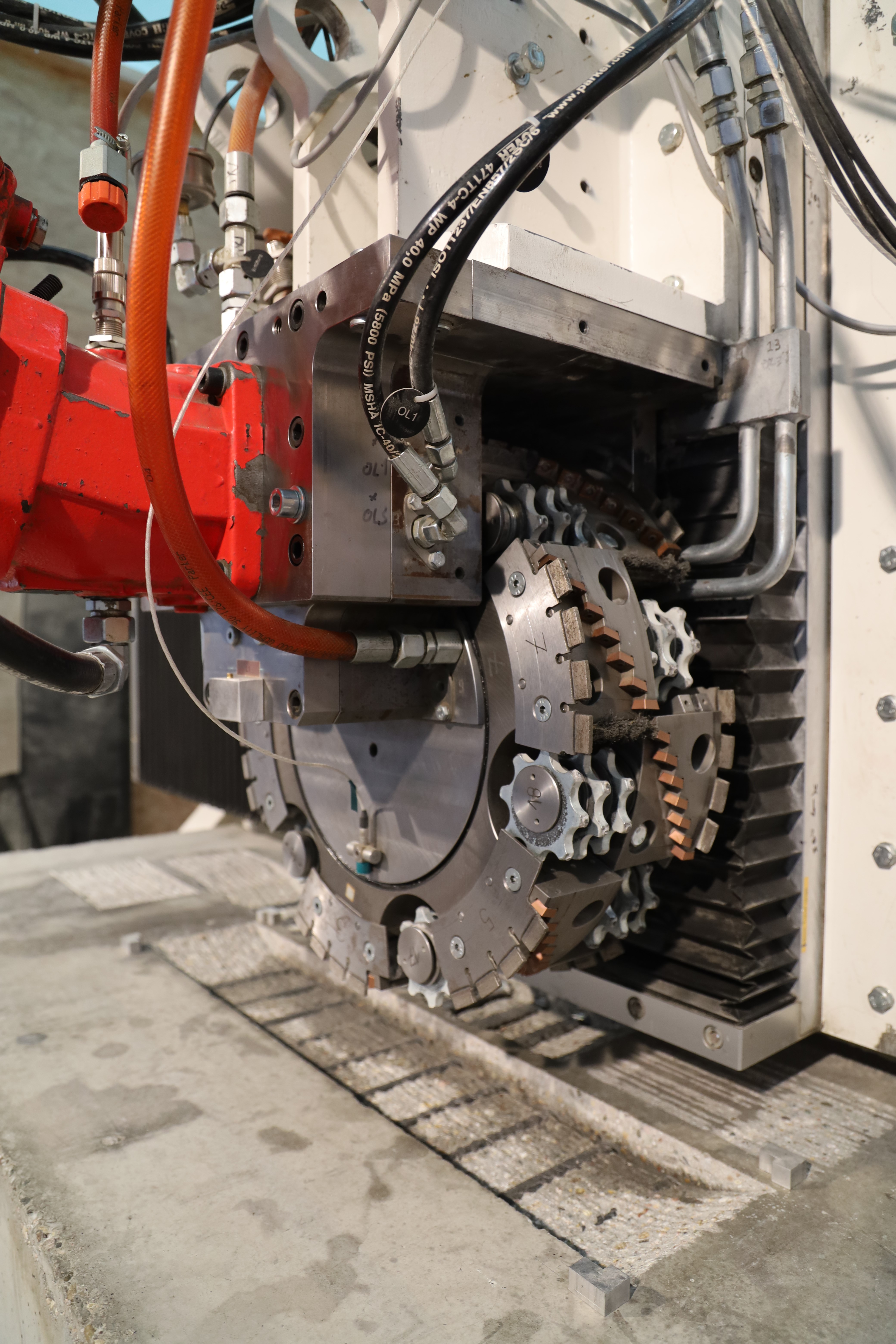

Mobile attachment for automated crack milling (MAARISS)

- Contact:

- Funding:

Federal Ministry of Education and Research

- Partner:

- Startdate:

01.11.2020

- Enddate:

31.10.2023

The aim of the project between science and industry is to develop a new mobile attachment for automated crack milling for use in nuclear facilities with innovative extraction technology and operating concept. Contamination is not only be present on the surface of wall structures, it can also penetrates deeply into cracks, it is necessary to uncover this crack in order to measure a structure. In the single-operator concept, the attachment should be easy, reliable and safe to control.

For this purpose, the research results from INAS (ablation and cutting technologies in a process combination of undercutting and milling technology) and DefAhS (cutting process of highly reinforced concrete by means of a combination tool consisting of indexable inserts and impact lamellas) are transferred to a demonstrator for use in a nuclear facility. With the development of a combination tool and the successful removal of highly reinforced concrete, the DefAhS research project clearly demonstrated the process and feasibility. As a result of the research, however, it was also shown that it is necessary to achieve a significant improvement in material removal. The goal in MAARISS is therefore, among other things, a new development of the extraction directly at the removal unit and an automation for use in a nuclear facility. Here, cracks are to be automatically milled over in order to enable a subsequent clearance measurement by the personnel on site. The physically very strenuous work of crack uncovering is to be reduced to only one operator in a safe environment. There will be no need to erect scaffolding at all and existing transport technology (forklift or cherry picker) will be used. This means that no other technology is required apart from the milling unit as an attachment for the transport technology. Downstream, already existing suction units are also to be used. Since not only cracks have to be milled out, but also joints that have been partially grouted with PCB-containing compound, the new process can also be used there.

and indexable inserts

© KIT-TMB