Validation of a continuous magnetic filter and sieving system for the treatment of particulate mixtures (KoMaSi)

- Contact:

Dr.-Ing. Dipl.-Phys. Carla-Olivia Krauß

(Junior research group leader)

- Funding:

Federal Ministry of Education and Research

- Startdate:

01.07.2024

- Enddate:

30.06.2027

Dismantling the reactor pressure vessel (RPV) and its internals is a major challenge. One dismantling method that has many technical advantages over other methods is the water-abrasive suspension cutting technique. In this method, a water-abrasive suspension is forced through a nozzle at high pressure and directed at the material to be cut. The water-abrasive-jet hits the radioactive steel of the RPV and thus cuts it. This produces large quantities of a waste mixture of inactive abrasive particles and radioactive kerf material, which must be disposed of as radioactive waste.

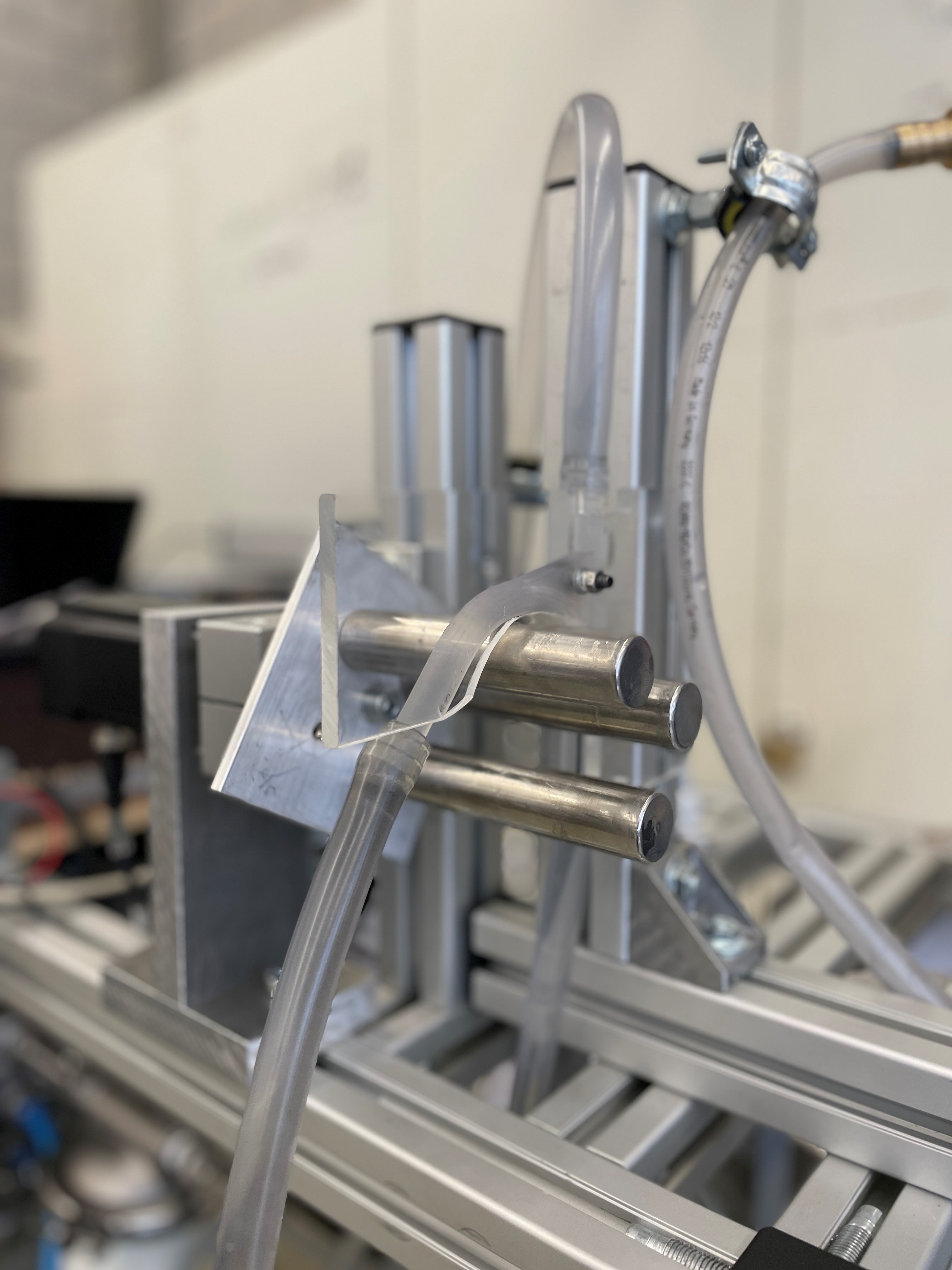

In the previous NaMaSK project, a separation system was developed that reduces this secondary waste by separating the particle mixture of the WAS cut into two fractions. One fraction consists of small, magnetic particles (steel particles and broken abrasive particles), which are disposed of as radioactive waste. The other fraction consists of intact abrasive particles that can be reused for a new WAS cut. The separation system consists of a sieve and a magnetic filter. With a separation setup in batch operation, it has been proven that the secondary waste can be reduced by 50-75 % (Patent for the separation plant and separation process). The separation system has been improved and consists of a continuously operated sieve and magnetic filter. An invention disclosure was also submitted for the newly developed magnetic filter.

In the KoMaSi project, both the sieve and the magnetic filter will be improved and adapted for use in the nuclear sector. A system with both components is then to be built and tested, taking into account the special requirements of nuclear applications. Commercial realisation after completion of the project can take place either through cooperation with companies or through a spin-off.

abrasive waste from the water-abrasive-

suspension-cutting

© KIT-TMB

magnetic filter

© KIT-TMB

© KIT-TMB